Basic overview of spray drying

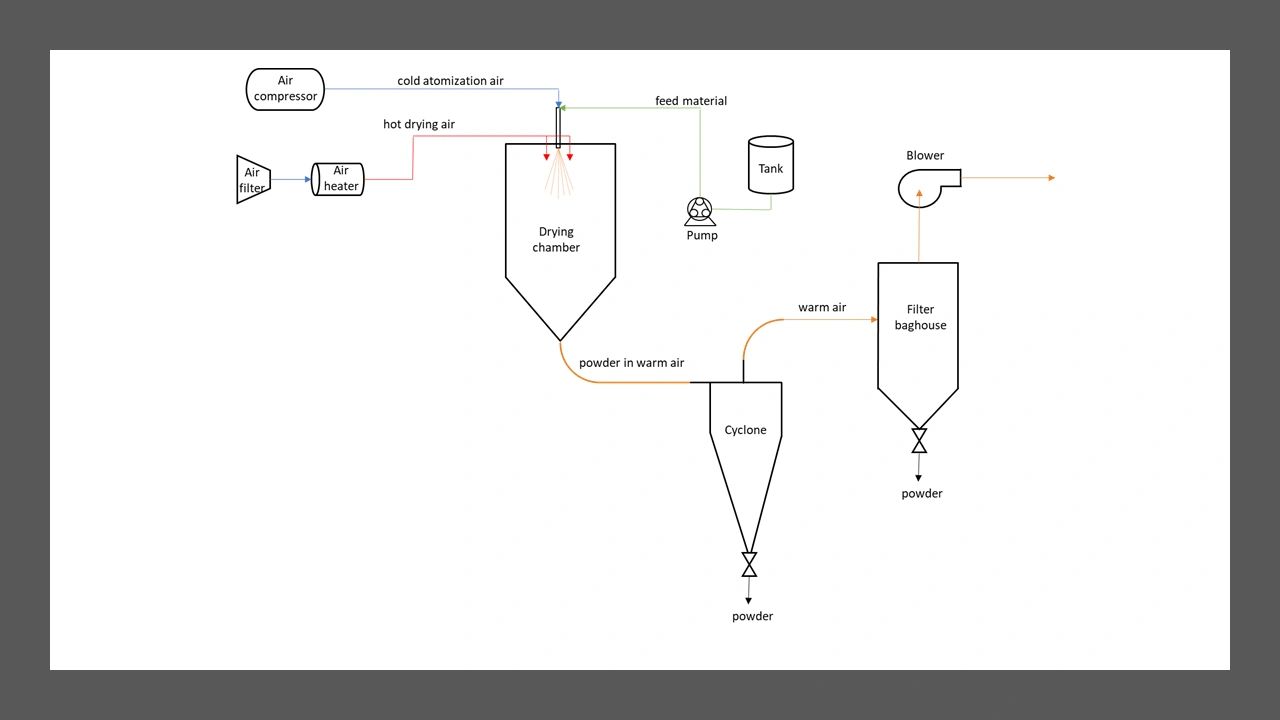

Spray drying is a continuous-flow method of producing powders from a solution or slurry in which fast moving, hot, drying gas (usually air) is used as both a heat transfer medium and a solids-conveying medium. A strong blower is used to force air from the surrounding environment sequentially through an air heater, drying chamber, cyclone and filter house. Simultaneously, the feed material is pumped through an atomization nozzle and into the drying chamber. The purpose of the atomization nozzle is to convert the feed liquid into a fine spray in which each droplet has a very small diameter and therefore a large surface area compared to its volume. The hot drying gas then transfers heat to the droplets which causes evaporation of the solution or slurry liquid (usually water). When done properly, the droplets will be completely dry before exiting the drying chamber and the drying chamber exhaust is a 2-phase system composed of solid powder particles suspended in the drying air which is now saturated with the evaporated slurry or solution liquid. In order to separate the solid particles from the saturated gas stream the exhaust is then moved through a cyclone and a filter in series. They cyclone uses centrifugal forces to separate the heavier particles from the gas stream and the filter uses size-exclusion to remove the finer particles from the gas stream. The saturated drying air is then exhausted into the surrounding environment. In some cases, it will pass through a wet scrubber or thermal oxidizer to comply with local emission regulations.

For a material to be a good candidate for spray drying technology it must be able to meet the following three objectives in a spray drying proof-of-concept test:

· Dry particles can be made

· A sufficient majority of the particles move through the drying chamber and do not stick to the walls of the chamber

· The particles can be adequately separated from the air stream

At Division by Zero Labs we can evaluate these three objectives to determine if your product is a good candidate for spray drying technology. Call and ask us about our low-cost proof-of-concept testing.

Copyright © 2017 Division by Zero labs - All Rights Reserved.